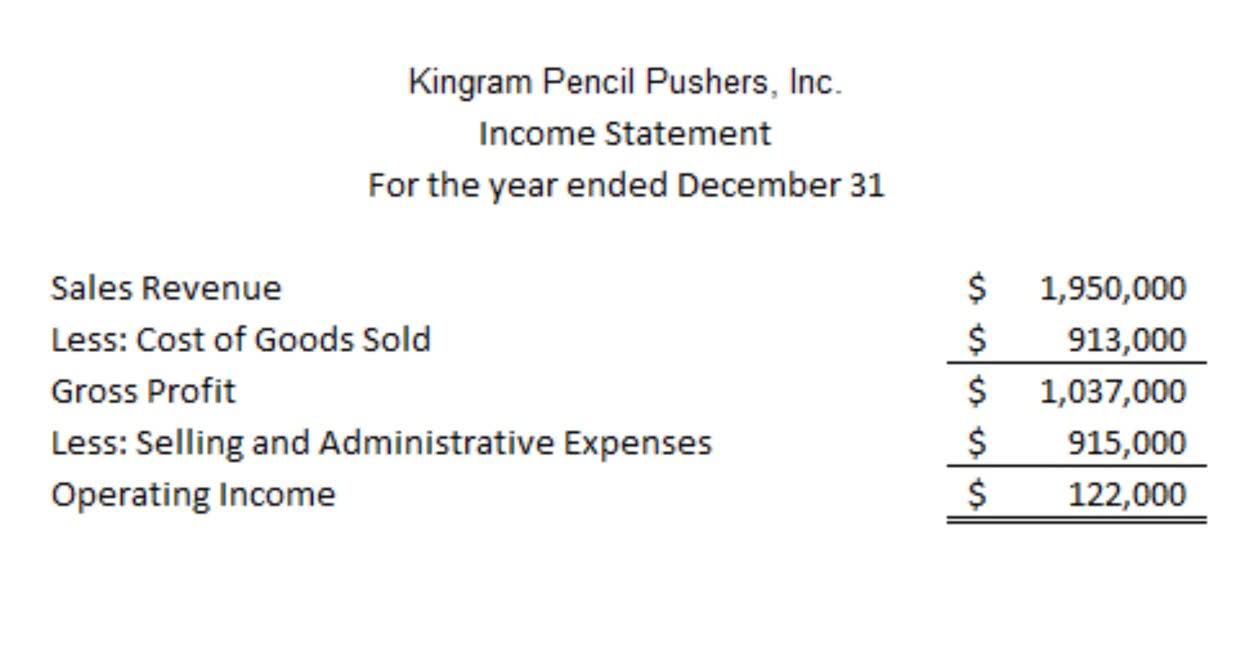

By estimating the per-unit cost, the entity can set an appropriate sales price and avoid under-pricing or over-pricing its products. The most crucial step of the whole budgeting Interior Design Bookkeeping process is determining the overall and expected product cost per unit (shirt). Also, the overall cost determined under the overhead budget is converted into per unit terms to determine the cost of ending inventory.

Price your products in line with the market:

You can determine production costs by adding together any labor costs and direct material costs. It’s important to also consider any of your manufacturing overhead costs. These direct costs can include everything from labor, raw materials, and supplies.

Over 200k developers and product managers use LogRocket to create better digital experiences

- Compensation, payroll taxes, and employee benefits should all be included in service product costs.

- In conclusion, understanding product cost is critical for the success of a business.

- These costs are capitalized as inventory and become part of the cost of goods sold when the product is sold.

- It’s also important to recognize that simply reducing production costs won’t necessarily generate more profit.

These costs are included as part of inventory and are charged against revenues as cost of sales only when the products are sold. In other words, they are initially classified as assets and are transferred to expense when they are sold. Another commonly used term for manufacturing costs is product costs, which also refer to the costs of manufacturing a product. Start by making a list of all the direct materials that are used to make the specific product and obtain the cost information for the direct materials you have identified. According to a study conducted by McKinsey, these indirect costs account for 8% to 12% of the overall manufacturing costs. Production costs are also referred to as manufacturing costs, product costs, and a manufacturer’s inventoriable costs.

Pricing Strategy:

The training company may charge for the hours worked by instructors in preparation and delivery of the course, plus a fee for the course materials. We’ll get into more detail about the types of production costs below, but in general, they can be many. Some costs of production are labor, raw materials, consumable manufacturing supplies and overhead.

- These costs include indirect labor, indirect materials, utilities, physical costs, financial costs, etc.

- These costs tend to be clustered into the selling, general and administrative classifications of expenses, and appear in the lower half of a reporting entity’s income statement.

- This wasn’t meant to be a pun, but product costs are also accounted for in accounting.

- It’s important to include all related costs of manufacturing the product when you calculate product cost.

- Businesses can negotiate favorable terms with suppliers and use just-in-time inventory systems to optimize costs.

Product cost is a practical concept that is used in a variety of industries and contexts. While personal finance can be daunting, the stakes are even higher when it comes to running a successful business. Without a solid understanding of where your expenses are going, you risk losing money and valuable resources. LogRocket identifies friction points in the user experience so you can make informed decisions about product and design changes that must happen to hit what are product costs your goals. With LogRocket, you can understand the scope of the issues affecting your product and prioritize the changes that need to be made.

This is because the cost of the fixed assets used to produce the balance sheet product is included in the manufacturing overhead cost, which is then included in the total product cost. Understanding the costs of a product or service allows companies to make informed decisions about pricing, production, and more. Not only does it help ensure that products are priced competitively, but it also helps ensure that they are profitable and sustainable in the long run. Managing product and production costs is essential for a successful business operation.